ECO mode Ram 1500 2014 Get to Know Guide

[x] Cancel search | Manufacturer: RAM, Model Year: 2014, Model line: 1500, Model: Ram 1500 2014Pages: 252, PDF Size: 6.74 MB

Page 130 of 252

FIVE-POSITION/ON-DEMAND TRANSFER CASE

This electronically shifted transfer case

provides five mode positions:

• Two-wheel drive high range (2WD)

•

Four-wheel drive automatic range (4WD

AUTO)

• Four-wheel drive lock range (4WD LOCK)

•

Four-wheel drive low range (4WD LOW)

• NEUTRAL (N)

This electronically shifted transfer case is

designed to be driven in the two-wheel

drive position (2WD) or four-wheel drive

position (4WD AUTO) for normal street

and highway conditions on dry, hard-

surfaced roads.

Driving the vehicle in 2WD will have greater fuel economy benefits as the front axle

is not engaged in 2WD.

Shifting Procedure

Shifting between 2WD and 4WD AUTO or 4WD LOCK can be made with the vehicle

stopped or in motion at speeds up to 55 mph (88 km/h).

Shifting between 2WD, 4WD AUTO and 4WD LOCK into 4WD LOW must be made

with the transmission in NEUTRAL and the vehicle stopped or rolling at 2 to 3 mph

(3 to 5 km/h).

NOTE:

It is preferred to have the engine running and the vehicle moving at 2 to 3 mph (3 to

5 km/h).

WARNING!

You or others could be injured if you leave the vehicle unattended with the transfer

case in the NEUTRAL position without first fully engaging the parking brake. The

transfer case NEUTRAL position disengages both the front and rear driveshafts

from the powertrain and will allow the vehicle to move regardless of the transmis-

sion position. The parking brake should always be applied when the driver is not

in the vehicle.

OFF-ROAD CAPABILITIES

128

Page 140 of 252

TOW/HAUL MODE

• When driving in hilly areas, towing a trailer, carrying a heavy load, etc., andfrequent transmission shifting occurs, press the TOW/HAUL switch to select

TOW/HAUL mode. This will improve performance and reduce the potential for

transmission overheating or failure due to excessive shifting. When operating in

TOW/HAUL mode, transmission upshifts are delayed, and the transmission will

automatically downshift (for engine braking) during steady braking maneuvers.

• The “TOW/HAUL Indicator Light” will illuminate in the instrument cluster to

indicate that TOW/HAUL mode has

been activated. Pressing the switch a

second time restores normal operation.

If the TOW/HAUL mode is desired, the

switch must be pressed each time the

engine is started.

INTEGRATED TRAILER BRAKE MODULE

The Integrated Trailer Brake Controller allows you to automatically or manually

activate the Electric Trailer Brakes and Electric Over Hydraulic Trailer Brakes for a

better braking performance when towing a trailer.

NOTE:

The Integrated Trailer Brake Controller is located in the center stack below the

climate controls.

This module will have four different options depending on the type of trailer you want

to tow and can be selected through the 3.5” Electronic Vehicle Information Center

(EVIC) or touchscreen radio.

• Light Electric

• Heavy Electric

• Light EOH (Electric Over Hydraulic)

• Heavy EOH (Electric Over Hydraulic)

UTILITY

138

Page 144 of 252

Shifting Into NEUTRAL (N)

Use the following procedure to prepare your vehicle for recreational towing.

WARNING!

You or others could be injured or killed if you leave the vehicle unattended with the

transfer case in the NEUTRAL (N) position without first fully engaging the parking

brake. The transfer case NEUTRAL (N) position disengages both the front and rear

driveshafts from the powertrain and will allow the vehicle to move, even if the

transmission is in PARK. The parking brake should always be applied when the

driver is not in the vehicle.

CAUTION!

It is necessary to follow these steps to be certain that the transfer case is fully in

NEUTRAL (N) before recreational towing to prevent damage to internal parts.

1. Bring the vehicle to a complete stop, with the engine running. Firmly apply the parking brake.

2. Shift the transmission to NEUTRAL.

3. Press and hold the brake pedal.

4. Depress the clutch pedal on a manual transmission.

5. If the transfer case is in 4WD AUTO (if equipped), press a selector button or rotate the selector switch to shift the transfer case into the 2WD or 4WD LOCK position.

• With manual shift transfer case, shift the transfer case lever into NEUTRAL (N).

• With electronic shift transfer case, press and hold the transfer case NEUTRAL (N) button. Some models have a small, recessed "N" button (at the center of the

transfer case switches) that must be pressed using a ballpoint pen or similar

object. Other models have a rectangular NEUTRAL switch, below the rotary

transfer case control knob. The NEUTRAL (N) indicator light will blink while the

shift is in progress. The light will stop blinking (stay on solid) when the shift to

NEUTRAL (N) is complete. After the shift is completed and the NEUTRAL (N)

light stays on, release the NEUTRAL (N) button.

6. Release the parking brake.

7. Shift the transmission into REVERSE.

8. Release the brake pedal (and clutch pedal on manual transmissions) for five seconds and ensure that there is no vehicle movement.

9. Repeat steps 7 and 8 with automatic transmission in DRIVE or manual transmis- sion in first gear.

10. Shift the transmission to NEUTRAL. Firmly apply the parking brake. Turn OFF the engine. For vehicles with Keyless Enter-N-Go™, press and hold the ENGINE

START/STOP button until the engine shuts off.

UTILITY

142

Page 159 of 252

DIESEL EXHAUST BRAKE (ENGINE BRAKING)

The Exhaust Brake switch is located on the switch bank below the audio system. This

switch is used to enable exhaust brake modes.

• Pressing the exhaust brake switch once will enable full strength exhaust brakemode, indicated by a yellow icon in the EVIC. This mode applies full exhaust

braking when the accelerator pedal is released. This is most useful for slowing the

vehicle.

• Pressing the exhaust brake switch again will enable the Smart Brake feature, indicated by a green icon in the EVIC. This feature is intended to maintain the

vehicle speed present when the accelerator pedal is released. However, when the

brakes are applied, full exhaust braking is still enabled to slow the vehicle.

• A third press of the brake switch will turn the exhaust brake off, and will extinguish the exhaust brake icon in the EVIC.

NOTE:

In general, higher engine speeds result in higher exhaust braking force. For optimum

braking power, it is recommended to use the exhaust brake while in TOW/HAUL

mode.

CAUTION!

Use of aftermarket exhaust brakes is not recommended and could lead to engine

damage.

WARNING!

Do not use the exhaust brake feature when driving in icy or slippery conditions as

the increased engine braking can cause the rear wheels to slide and the vehicle to

swing around with the possible loss of vehicle control, which may cause a collision

possibly resulting in personal injury or death.

6.7L CUMMINS® DIESEL

157

Page 162 of 252

UNDERBODY MOUNTED FUEL FILTER/WATER SEPARATOR

Draining Fuel/Water Separator

•If the “Water in Fuel” indicator lightis illuminated and an audible chime is

heard five times, you should stop the engine and drain the water from the separator.

• The drain is located on the bottom of the Fuel Filter and Water Separator assembly which is located in front of the rear axle above the drive shaft on pick up models.

The Chassis Cab models second filter location is on the frame behind the front

axle. The best access to this water drain valve is from under the vehicle.

• Turn the drain valve (located on the side of the filter) counterclockwise 1 full turn, then turn the ignition switch to the ON/RUN position to allow any accumulated

water to drain.

• When clean fuel is visible, close the drain and switch the ignition to OFF.

• Refer to the Diesel Supplement on the DVD for further details.

Underbody Fuel Filter Replacement

• With the engine off and a drain pan under the fuel filter drain hose, open the water drain valve 1 full turn counterclockwise and completely drain fuel and water into

the approved container.

• Close the water drain valve and remove the lid using a socket or strap wrench; rotate counterclockwise for removal. Remove the used o-ring and discard it.

• Remove the used filter cartridge from the housing and dispose of according to your local regulations.

• Wipe clean the sealing surfaces of the lid and housing and install the new o-ring into ring groove on the filter housing and lubricate with clean engine oil.

• Install a new filter in the housing. Push down on the cartridge to ensure it is properly seated. Do not pre-fill the filter housing with fuel.

• Start the engine and confirm no leaks are present.

The underbody mounted filter housing will cause the engine not to run if:

1. No filter is installed.

NOTE:

• Using a fuel filter that does not meet the manufacturer's filtration and water separating requirements can severely impact fuel system life and reliability.

• The WIF sensor is re-usable. Service kit comes with new o-ring for filter canister and WIF sensor.

6.7L CUMMINS® DIESEL

160

Page 188 of 252

Hub Caps/Wheel Covers

• The hub caps must be removed before raising the vehicle off the ground.

• For single rear-wheel (SRW) models, use the blade on the end of the lug wrenchto pry the hub cap off. Insert the blade end into the pry-off notch and carefully pop

off the hub cap with a back-and-forth motion.

• On models with dual rear wheels (DRW), you must first remove the hub caps. The jack handle driver has a hook at one end that will fit in the pry off notch of the rear

hub caps. Position the hook and pull out on the ratchet firmly. The hub cap should

pop off. The wheel skins can now be removed. For the front hub cap use the blade

on the end of the lug wrench to pry the caps off. The wheel skin can now be

removed.

• You must use the flat end of the lug wrench to pry off the wheel skins. Insert the flat tip completely and using a back-and-forth motion, loosen the wheel skin.

Repeat this procedure around the tire until the skin pops off.

• Replace the wheel skins first using a rubber mallet. When replacing the hub caps, tilt the cap retainer over the lug nut bolt circle and strike the high side down with

a rubber mallet. Be sure that the hub caps and wheel skins are firmly seated

around the wheel.

Wheel Nuts

All wheel nuts should be tightened occasionally to eliminate the possibility of wheel

studs being sheared or the bolt holes in the wheels becoming elongated. This is

especially important during the first few hundred miles/kilometers of operation to

allow the wheel nuts to become properly set. All wheel nuts should first be firmly

seated against the wheel. The wheel nuts should then be tightened to recommended

torque. Tighten the wheel nuts to final torque in increments. Progress around the bolt

circle, tightening the wheel nut opposite to the wheel nut just previously tightened

until final torque is achieved. Recommended torques are shown in the following

chart.

Disc Wheels

Nut Type Stud Size Hex Size Torque

Ft LbsTorque

Newton Meters

Cone M14 x 1.5 22 mm 120-150 160-200

Flanged M14 x 1.5 22 mm 130-160 190-220

WHAT TO DO IN EMERGENCIES

186

Page 189 of 252

8-Stud — Dual Rear Wheels

• Dual wheels are flat-mounted and center-piloted. The lug nuts are a two-pieceassembly. When the tires are being rotated or replaced, clean these lug nuts and

add two drops of oil at the interface between the hex and the washer.

• Slots in the wheels will assist in prop- erly orienting the inner and outer

wheels. Align these slots when assem-

bling the wheels for best access to the

tire valve on the inner wheel. The tires

of both dual wheels must be com-

pletely off the ground when tightening,

to ensure wheel centering and maxi-

mum wheel clamping.

• Dual wheel models require a special heavy-duty lug nut tightening adapter

(included with the vehicle) to correctly

tighten the lug nuts. Also, when it is necessary to remove and install dual rear

wheels, use a proper vehicle lifting device.

NOTE:

When installing a spare tire as part of a dual rear wheel end combination, the tire

diameter of the two individual tires must be compared. If there is a significant

difference, the larger tire should be installed in a front location. The correct direction

of rotation for dual tire installations must also be observed.

These dual rear wheels should be tightened as follows:

1. Tighten the wheel nuts in the num- bered sequence to a snug fit.

2. Retighten the wheel nuts in the same sequence to the torques listed in the

table. Go through the sequence a

second time to verify that specific

torque has been achieved. Retighten to

specifications at 100 miles (160 km)

and after 500 miles (800 km).

• It is recommended that wheel stud

nuts be kept torqued to specifications

at all times. Torque wheel stud nuts to specifications at each lubrication interval.

WHAT TO DO IN EMERGENCIES

187

Page 198 of 252

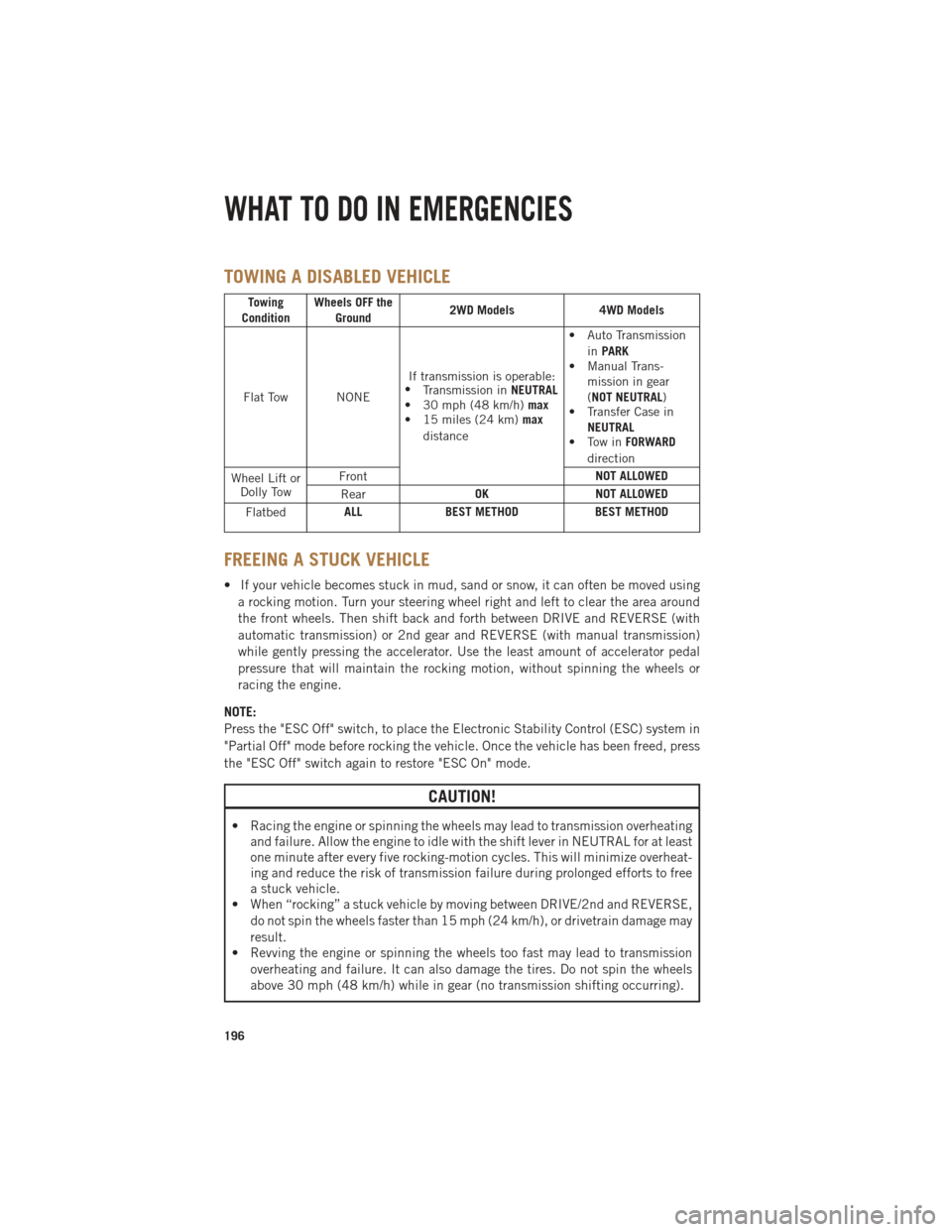

TOWING A DISABLED VEHICLE

Towing

Condition Wheels OFF the

Ground 2WD Models

4WD Models

Flat Tow NONE If transmission is operable:

• Transmission in NEUTRAL

• 30 mph (48 km/h) max

• 15 miles (24 km) max

distance • Auto Transmission

inPARK

• Manual Trans-

mission in gear

(NOT NEUTRAL)

• Transfer Case in

NEUTRAL

• Tow in FORWARD

direction

Wheel Lift or Dolly Tow Front

NOT ALLOWED

Rear OK

NOT ALLOWED

Flatbed ALL

BEST METHOD BEST METHOD

FREEING A STUCK VEHICLE

• If your vehicle becomes stuck in mud, sand or snow, it can often be moved using

a rocking motion. Turn your steering wheel right and left to clear the area around

the front wheels. Then shift back and forth between DRIVE and REVERSE (with

automatic transmission) or 2nd gear and REVERSE (with manual transmission)

while gently pressing the accelerator. Use the least amount of accelerator pedal

pressure that will maintain the rocking motion, without spinning the wheels or

racing the engine.

NOTE:

Press the "ESC Off" switch, to place the Electronic Stability Control (ESC) system in

"Partial Off" mode before rocking the vehicle. Once the vehicle has been freed, press

the "ESC Off" switch again to restore "ESC On" mode.

CAUTION!

• Racing the engine or spinning the wheels may lead to transmission overheating and failure. Allow the engine to idle with the shift lever in NEUTRAL for at least

one minute after every five rocking-motion cycles. This will minimize overheat-

ing and reduce the risk of transmission failure during prolonged efforts to free

a stuck vehicle.

• When “rocking” a stuck vehicle by moving between DRIVE/2nd and REVERSE,

do not spin the wheels faster than 15 mph (24 km/h), or drivetrain damage may

result.

• Revving the engine or spinning the wheels too fast may lead to transmission

overheating and failure. It can also damage the tires. Do not spin the wheels

above 30 mph (48 km/h) while in gear (no transmission shifting occurring).

WHAT TO DO IN EMERGENCIES

196

Page 207 of 252

FLUIDS AND CAPACITIES

Gasoline Versions

ComponentFluid, Lubricant, or

Genuine Part Capacities

Engine Coolant

3.6L Engine We recommend you use

MOPAR

®Antifreeze/

Coolant 10 Year/150,000

Mile Formula OAT (Organic Additive Technology). 14 Quarts (13 Liters)

Engine Coolant

5.7L 1500 Models We recommend you use

MOPAR

®Antifreeze/

Coolant 10 Year/150,000

Mile Formula OAT (Organic Additive Technology). 16 Quarts (15 Liters)

Engine Coolant

5.7L 2500/3500 Models We recommend you use

MOPAR

®Antifreeze/

Coolant 10 Year/150,000

Mile Formula OAT (Organic Additive Technology) . 18.7 Quarts (17.7 Liters)

Engine Coolant

5.7L 2500/3500 Models

w/Heavy Duty We recommend you use

MOPAR

®Antifreeze/

Coolant 10 Year/150,000

Mile Formula OAT (Organic Additive Technology) . 19.2 Quarts (18.2 Liters)

Engine Coolant

6.4L 2500/3500 Models We recommend you use

MOPAR

®Antifreeze/

Coolant 10 Year/150,000

Mile Formula OAT (Organic Additive Technology) . 18.7 Quarts (17.7 Liters)

Engine Coolant

6.4L 2500/3500 Models

w/Heavy Duty We recommend you use

MOPAR

®Antifreeze/

Coolant 10 Year/150,000

Mile Formula OAT (Organic Additive Technology) . 19.2 Quarts (18.2 Liters)

Engine Oil with Filter

3.6L, 5.7L We recommend you use

API Certified SAE 5W-20 Engine Oil, meeting the

requirements of Chrysler Material Standard

MS-6395 such as

MOPAR

®, Pennzoil®,and

Shell Helix®. Refer to your

engine oil filler cap for correct SAE grade. 3.6L Engine - 6 Quarts

(5.7 Liters)

5.7L Engine - 7 Quarts (6.6 Liters)

MAINTAINING YOUR VEHICLE

205

Page 209 of 252

ComponentFluid, Lubricant, or

Genuine Part Capacities

Automatic Transmission –

Eight-Speed Automatic Use only MOPAR

®ZF

8&9 Speed ATF™ Auto-

matic Transmission Fluid, or equivalent. Failure to

use the correct fluid may affect the function orperformance of your transmission. —

Automatic Transmission –

Six-Speed Automatic with

Gasoline Engine We recommend you use

only ATF+4

®Automatic

Transmission Fluid. Failure to use ATF+4

®fluid may

affect the function or

performance of your trans- mission. We recommendMOPAR

®ATF+4®fluid. —

Transfer Case We recommend you use

MOPAR

®BW44–44

Transfer Case Fluid. —

Front Axle 1500

Four-Wheel Drive Models We recommend you use

MOPAR

®GL-5 Synthetic

Axle Lubricant SAE 75W-85. —

Rear Axle 1500 Models We recommend you use

MOPAR

®Synthetic Gear

Lubricant SAE 75W-140

(MS-8985). Limited-Slip Rear Axles require the

addition of 5 oz. (148 ml) MOPAR

®Limited Slip

Additive (MS-10111). —

Front and Rear Axle –

2500/3500 Models We recommend you

use Synthetic, GL-5

SAE 75W-85. Limited slip

additive is not required for Limited-Slip Rear Axles. —

Brake Master Cylinder We recommend you use

MOPAR

®DOT 3 and

SAE J1703. If DOT 3 is

not available, then DOT 4 is acceptable. —

MAINTAINING YOUR VEHICLE

207